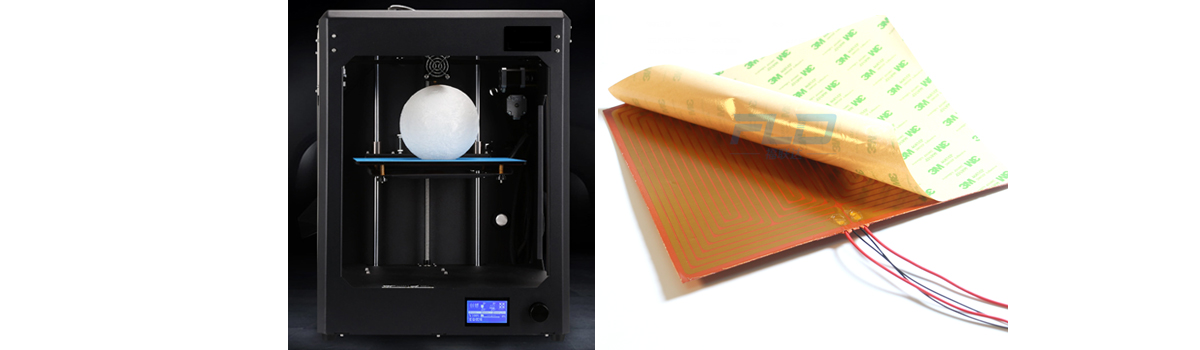

The 3D printer hot bed is a unique accessory for FDM (melt-stack) printers. It is a polyimide heater pad or a silicone heater sheet attached to the bottom of the hot bed. The main purpose is to prevent curling during 3D printing. So why is 3D printing curled? The curling is caused by the cooling shrinkage of the material. The shrinkage rates of different materials are different, so the degree of warping is also different, but one thing is certain, the curling edge is certain and inevitable, and only the influence of the curling edge can be alleviated. So some people think that printing PLA does not require a hot bed. In fact, this idea is wrong. Printing PLA from different manufacturers has different effects. Some of the edges are not obvious, and some will be very serious.

Hot beds can't eradicate the edges, only reduce the weakened edges. The main principle is to heat the hot bed through the heater pad to maintain the print at a higher temperature (PLA 60 ° C ABS 100 ° C), which can prevent the material from cooling during the printing process, thus reducing the model curl.

Polyimide heater pad and silicone heater sheet can be customized according to customers' different requirements for external shape, size and voltage power. Easy to install and control temperature adjustment. It is currently the preferred product for 3D printing hot bed heating.

Emma

Emma